We will continue to build up our tempering expertise in Ohrdruf and can therefore offer our customers everything from a single source. Our customers thus also ultimately benefit from the vertical integration, which saves further processing steps.

Surface Tempering in Ohrdruf.

Fineblanked and formed parts are becoming lighter and smaller. At the same time, the demands on their strength are increasing. Likewise, the demand for procedures that improve their performance have increased over the past few years accordingly. For instance, in order to temper surfaces further, Feintool offers heat treatment processes using its own equipment – for example at our forming plant in Ohrdruf, Germany. Here, our tempering expertise is built up and expanded. Now, we no longer only manufacture formed parts, but these can also be processed directly on-site and delivered to the customer ready for assembly.

Plasma and gas: these two tempering processes have been in operation in Ohrdruf since the end of last year. We launched the project three years ago and, since then, a new factory hall has been built, plasma and gas furnaces have been purchased, and processes have been automated. In addition, we took over an existing plasma furnace from the plant in Obertshausen.

Production has now begun. As of the end of last year, we have been carrying out both plasma nitriding as well as gas nitriding.

What We Do during Plasma Nitriding

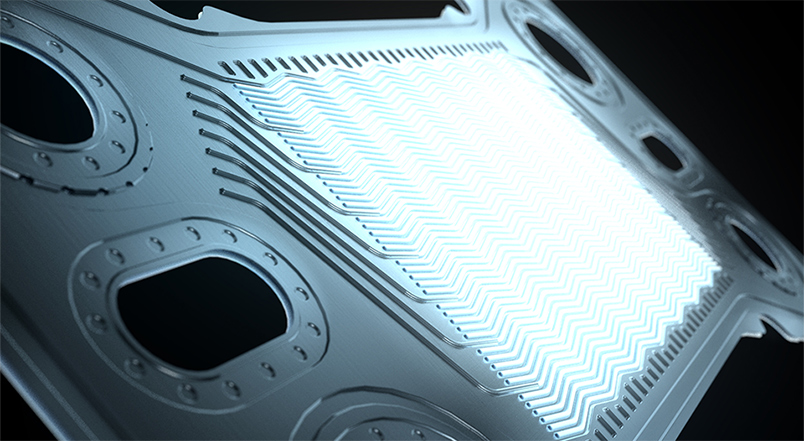

In plasma nitriding, the tempering of the surface is accomplished by bombarding it with nitrogen ions, which diffuse into the surface and thus lead to an increase in hardness. In gas nitriding, ammonia is split into hydrogen and reactive nitrogen, which then diffuses into the surface. In both processes, the border zone of the components is enriched with nitrogen in order to raise the surface hardness. By treating the surface, the durability and resistance of the formed parts are raised.

For us, the typical working range is between 500°C and 560°C for plasma nitriding and between 500°C and 580°C for gas nitriding. Tempering with gas nitriding takes ten to eleven hours; with plasma nitriding it takes almost twice as long.

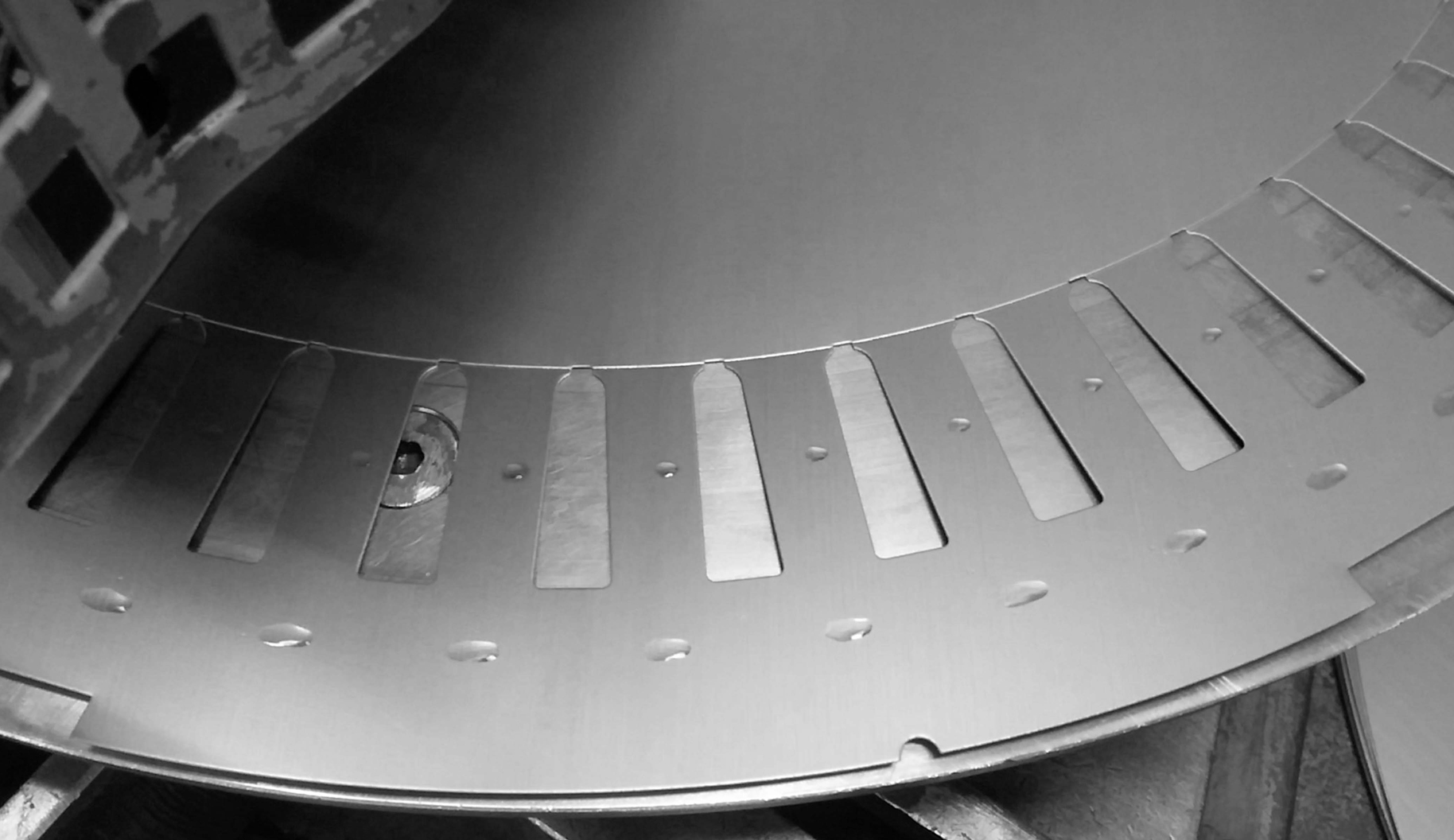

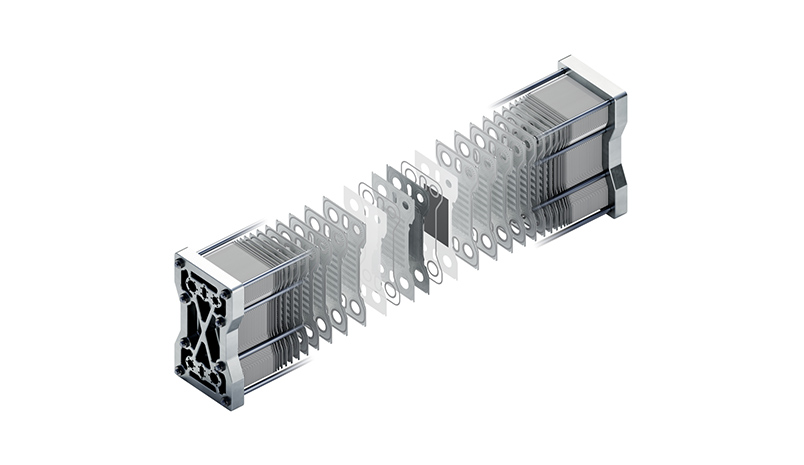

With plasma nitriding, individual spots can be omitted more easily than with gas nitriding. The desired areas on the formed part can be easily shielded from tempering using a heat-resistant cover on the components. Since the nitrogen ions can then no longer hit the covered area, this area is not tempered. This is then necessary, for example, if tempering would be an impediment to subsequent processing steps – such as capacitor discharge welding and in some cases laser welding. In order to cover entire areas, the parts are nitrided in specially designed racks.

How It Differs from Gas Nitriding

This kind of cover is not possible as simply for gas nitriding, since the area to be covered needs to be sealed gastight. This is only possible through special heat-resistant copper pastes, which is not an economical process for our requirements. One advantage would be to simply place the parts in baskets for gas nitriding.