For a new class of fuel cells

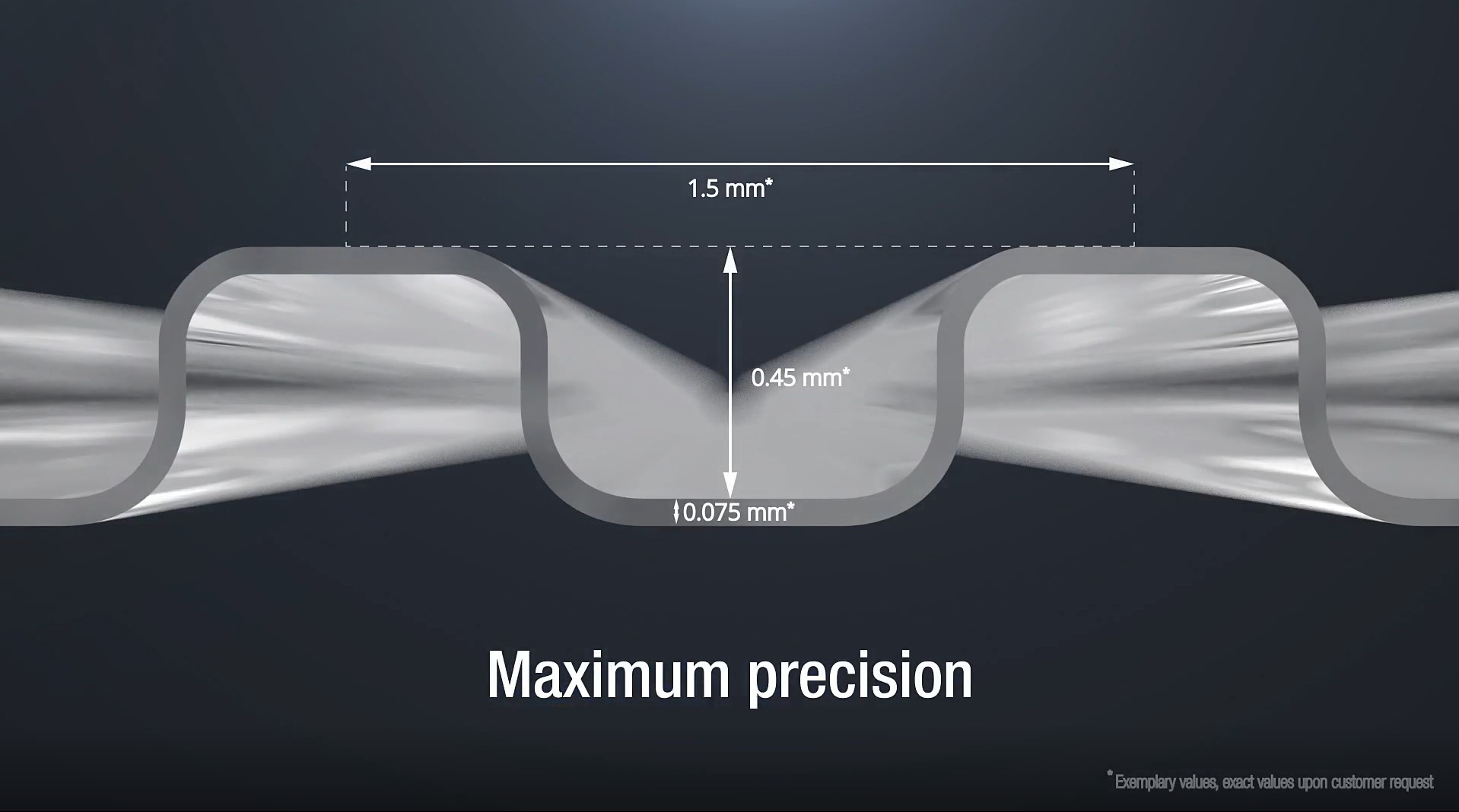

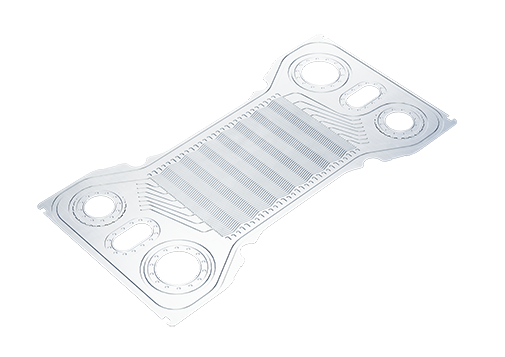

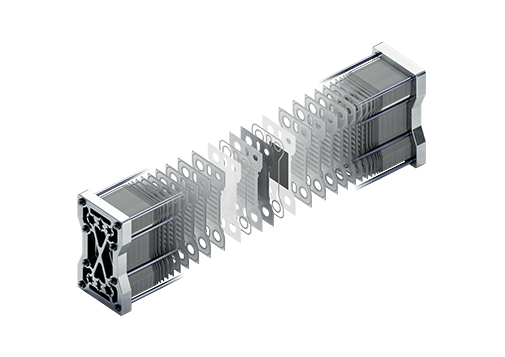

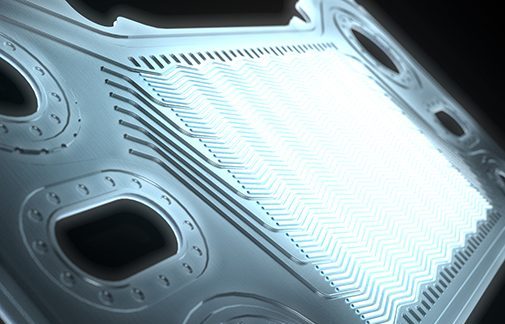

Feinforming makes it possible to process metals of the thinnest material thicknesses with minimal tolerances and maximum precision – crucial for the production of bipolar plates used in fuel cells and electrolyzers.

We optimize the use of materials, design implementation, and production to cut costs and increase the efficiency of fuel cell technology.