High-performance fuel cells through FEINforming: the key to future mobility.

The key to future mobility.

Hydrogen is poised to play a critical role in global industrial decarbonization. As a result, technological advances in recent years have been able to significantly reduce the costs of many hydrogen applications.

In January 2020, the “Hydrogen Council,” a global initiative of 81 leading energy, transportation, and industrial companies with a shared long-term vision for the development of the hydrogen economy, stated:

“We find that hydrogen can meet a large share of the mobility energy demand by 2030. Even with hydrogen costs at the gas pump of USD 6 per kg – including production, distribution, and retail – the fuel can meet about 15 per cent of transport energy demand cost competitively by 2030. We expect this cost profile to become viable in most regions and use cases by 2030. If costs were USD 4 per kg at the nozzle, hydrogen could even meet more than 50 per cent of the mobility sector’s energy demand.

Trucks, long-distance buses and large passenger vehicles are particularly competitive, as the cost of batteries required to secure the necessary range is very high for the battery alternatives.” ([1] Hydrogen Council – Path to hydrogen competitiveness; A cost perspective. January 10, 2020)

FEINforming: a key technology

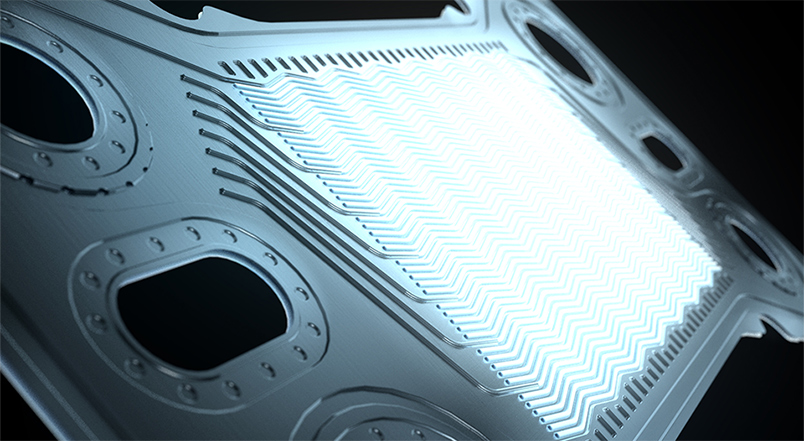

FEINforming is a forming process developed by Feintool for extremely thin metal sheets. It enables a leap in quality in the production of bipolar plates, the central component of PEM fuel cells installed in vehicles. FEINforming is a precision technology that allows the thinnest stainless steel sheets to be formed with extreme accuracy and minimal fault tolerances.

The goal is to achieve a degree of precision comparable to the dimensional accuracy of cast bipolar plates traditionally manufactured from graphite. Although these have an optimal shape, they also have some deleterious material properties that make them unsuitable for use in vehicles, such as brittleness, greater material thickness, greater weight, and the resulting lower power density. If they can be manufactured with precision, metallic bipolar plates are far superior in all of these aspects.

What makes a fuel cell powerful?

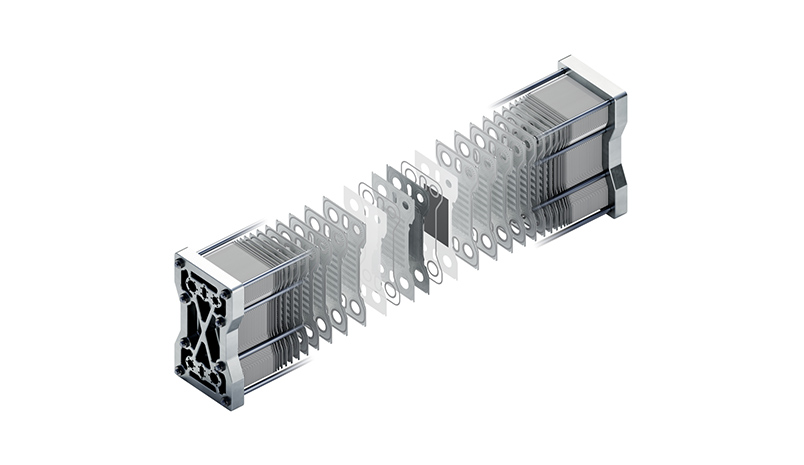

The objective is to fit as much power as possible into the smallest possible space. Depending on their capacity, several hundred individual fuel cell modules are stacked and connected in series in the fuel cell stack. The thinner the individual cell, the more compact the design, the lower the total weight, and the higher the power density, measured in kilowatts per unit of volume (kW/dm3). As the core element of the fuel cell stack, bipolar plates constitute the component that can play a decisive role in the breakthrough of the fuel cell. The bipolar plate must possess the following properties:

- Chemical stability against moist, oxidizing, and reductive conditions

- Gas-tightness

- Excellent electrical conductivity

- Low contact resistances

- Excellent plane-parallelism

- Low costs (production and material)

The role of the material and flow-field geometry

In general, coated metals (stainless steel, titanium, aluminum), graphite, or graphite-polymer composites are suitable materials for bipolar plates used in PEM fuel cells.

Overall, metallic bipolar plates have numerous advantages over graphite plates, such as lower weight, lower volume, and better cold-start properties. (See online article by author Christiane Köllner (in German): https://www.springerprofessional.de/brennstoffzelle/werkstoffe/warum-ist-die-bipolarplatte-fuer-brennstoffzellen-so-wichtig-/17286820)

Bipolar plates made of graphite make up a large percentage of the weight of a fuel cell and account for up to 40 percent of the fuel cell’s production costs. For this reason alone, metallic bipolar plates offer considerable cost-cutting potential in high-volume series production.

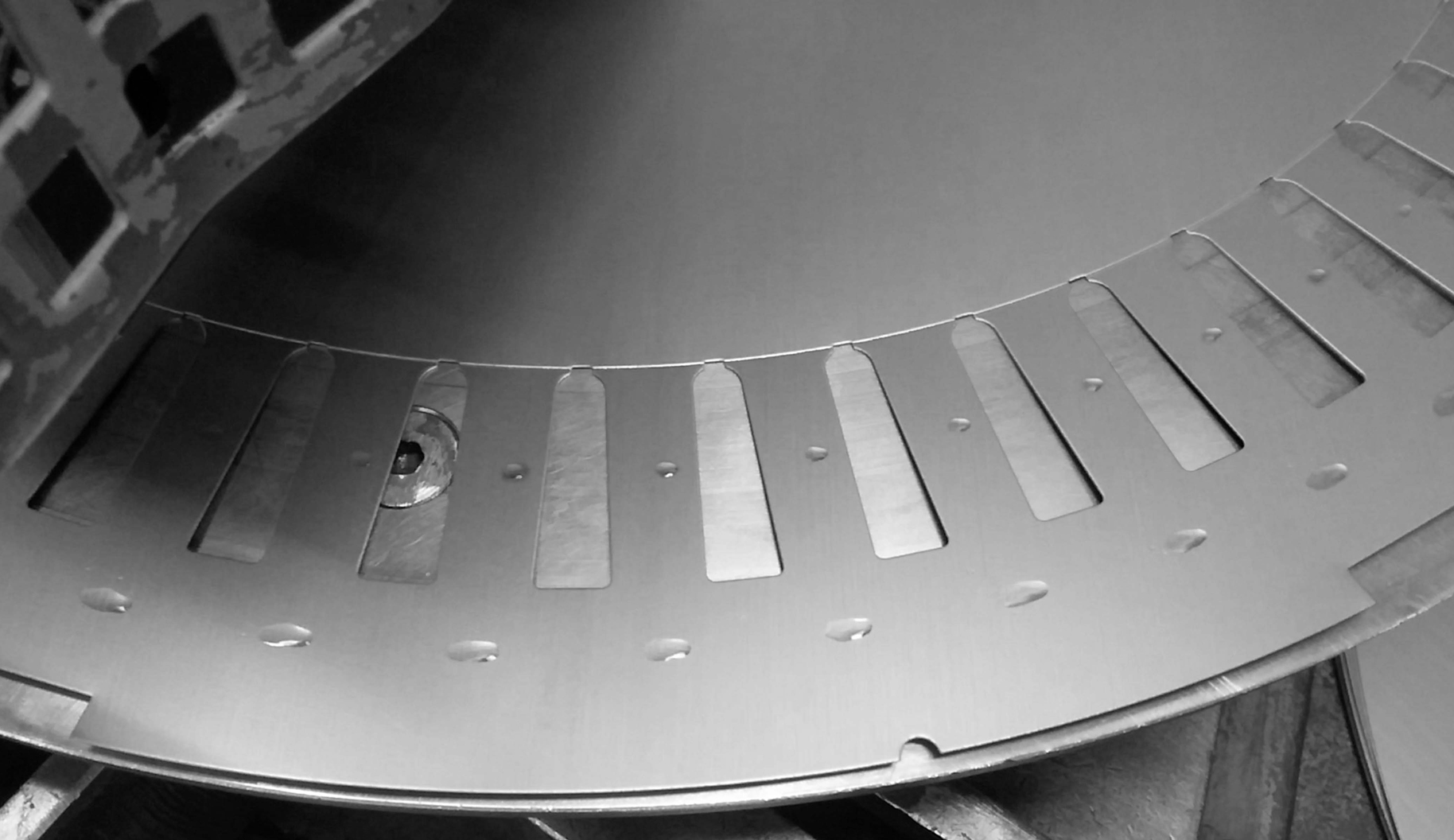

Between the bipolar plates, more precisely in the catalyst layer, hydrogen and oxygen react to form water, releasing energy in the form of electricity and heat. As an integrated module, the plates form the electrical connection between the cells, ensure that the gases are distributed over the surface of the plate as well as separated between adjacent cells and sealed off from the outside, and are responsible for cooling (dissipation of thermal energy).

Electrically, the bipolar plate acts as the cathode and anode. It contains extremely fine channels on both sides (referred to as flow profiles or the flow field) through which the gases are conducted and water, the reaction product, is removed. The geometrical properties of these channels play a critical role in the efficiency of the chemical and physical processes.

- Nearly perfect rectangularity

Right-angled channels maximize the cross section. Previous metal forming processes such as hydroforming or stamping are less geometrically accurate. When viewing the cross section, the channels created in flow-field geometry resemble sinusoidal curves rather than rectangular profiles. FEINforming can be used to create shapes with a high percentage of flat contact surfaces for the membrane electrode assembly (MEA). - Uniform forming with extremely tight tolerances

The principle behind FEINforming compensates for tolerances in the base material (i.e. the coil). These effects increase the resulting consistency of the channel height while maintaining a degree of reproducibility. - Furthermore, the process allows thinner sheets to be used due to the extremely uniform thinning without the critical reduction in the cross section or radii of the base material.

Why can Feintool produce higher-quality products with FEINforming?

The compatibility of the press and the tool is decisive. The FB one series, Feintool’s latest generation of hydraulic presses, is perfect for the production of bipolar plates. It achieves outstanding reproducibility at the highest production speeds.

On this basis and as a result of our decades of experience in the fields of fineblanking and forming technology, Feintool is committed to developing processes for its customers that help them achieve major technological leaps. In this context, precision, tolerance minimization, optimization, quality, and cost-effective processes and manufacturing methods all play a crucial role.

In conclusion, FEINforming is Feintool’s cutting-edge manufacturing process for the production of high-performance metal bipolar plates for fuel cells. In addition to membrane electrode assemblies (MEA), these plates constitute the key component of polymer electrolyte membrane fuel cells (PEM).

The company’s one-of-a-kind approach consists of simultaneously producing all of the internal and external geometries relevant to the stack as well as the flow field of the bipolar plates in an integrated process.

As a result, Feintool offers its customers and partners access to a highly economical and optimized production process for fuel-cell drives that are as powerful as they are compact for zero-emission electric vehicles or for stationary fuel cells.