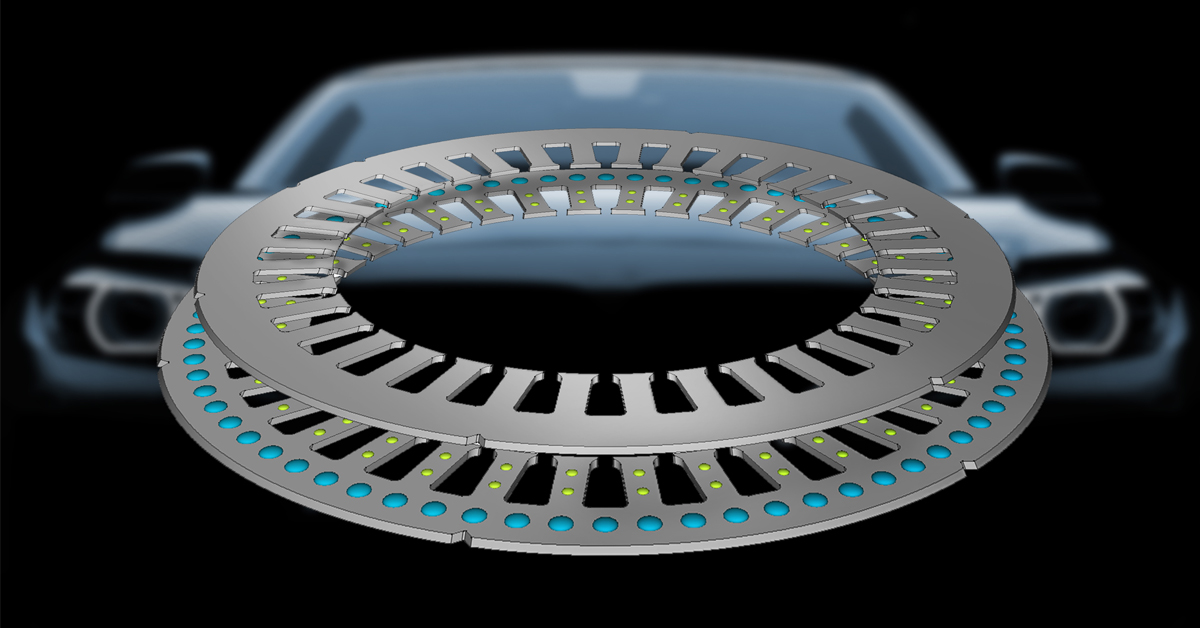

As the output of components decreases and their variety increases, laser-based production technologies are ideal for producing prototypes or small to medium quantities quickly and cost-effectively in a tool-free process.

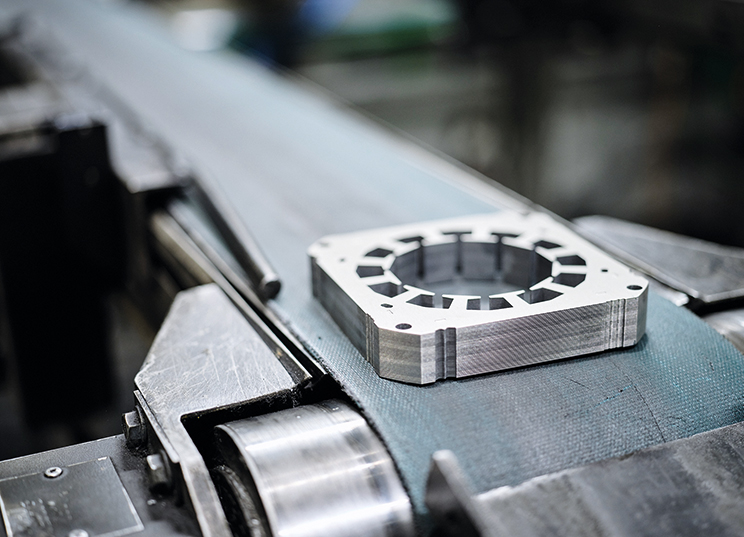

The solid-state and dual-head laser systems machine electrolaminations with thicknesses from 0.1 to 1.0 mm with an accuracy of a few hundredths of a millimeter.