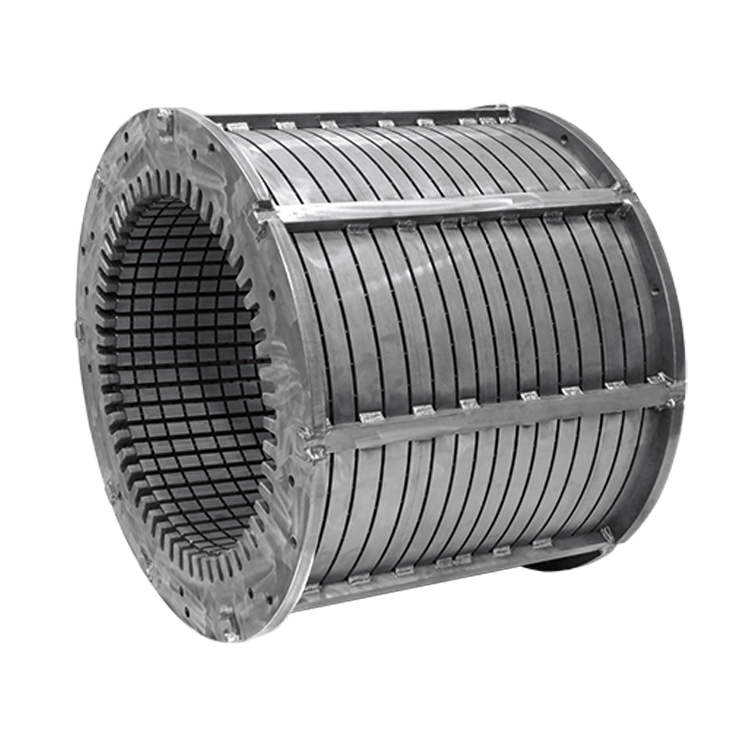

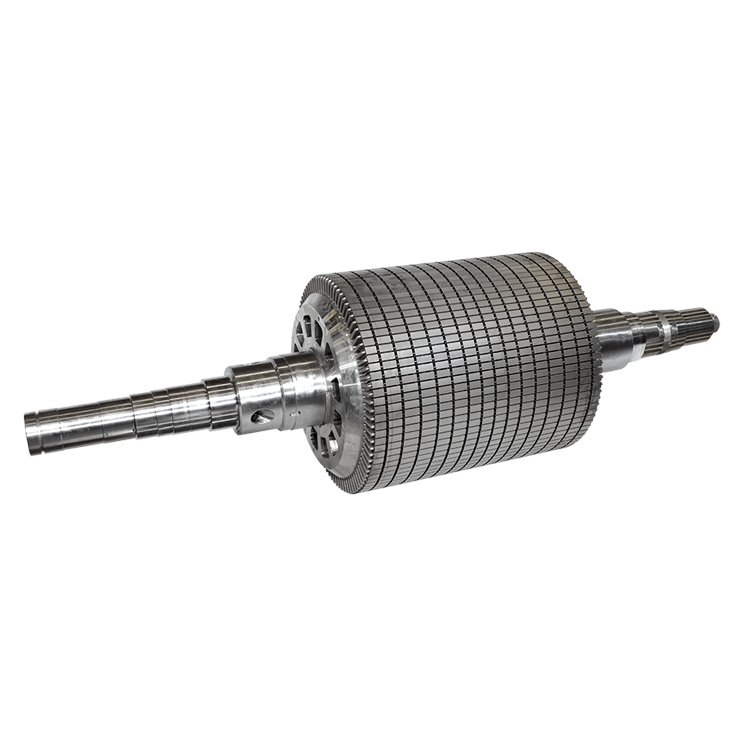

Rotors and stators for wind and hydro power

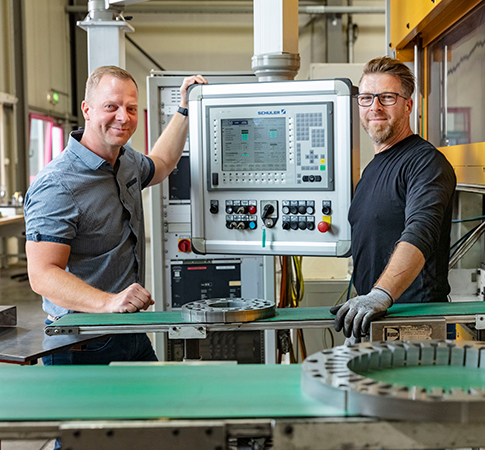

We achieve a high precision even for large sizes at competitive costs, thanks to our high-end electrolamination technology.

Take advantage of ultra-precision technologies in your Renewable Energy projects.

With our technologies, we achieve a high precision even for large components such as rotors and stators used in generators. Benefit from our expertise for more efficiency, lower tolerances and better quality.

Rotors and stators are the core components of generators for wind turbines and hydroelectric power plants. Although they are of considerable size, the manufacturing tolerances are low.

Even when it comes to large diameter layered sheets (cookies or segments), we maintain the same high degree of precision and standards as those used for electric motor cores for electric mobility.

For wind turbines, we produces rotor-stator stacks suitable for all sizes and power classes used worldwide for both onshore and offshore installations. Our services include everything from prototyping to pre-series with near serial tolerancing and high-volume production.

Depending on the intended application, we build ASM (externally excited asynchronous machine) and PSM (permanently magnet synchronous machine) cores.

As an innovator in the production of highly complex components and systems, we maximize performance and embrace innovation: from high-performance fineblanking or electrolamination stamping systems including tools and manufacturing processes to the optimization of entire process chain.

Benefit from our expertise to bring your project to the next level in terms of quality, cost-effectiveness and innovation for a long-term competitve advantage. We’re here to guide you towards the perfect fit for your goals and parameters, drawing on our long experience working with customers from all over the world in various industries.

Get in touch with us. We will be glad to help you.