Feintool technology forum part II.

The FB one press series provides answers to global challenges

The second part of the digital event series gave an in-depth insight into the FB one directly from the competence center for press construction in Jona. CEO Knut Zimmer and the Head of Unit Markus Schaltegger explained from the inside and René Aerts, Chief of Staff Art Group, from the customer’s point of view how Feintool’s latest press series sustainably maximizes output and availability with maximum flexibility in applications.

Steel prices are rising worldwide. The manufacturing industry does not have enough electrical components available. And last August, the key message of the sixth report of the Intergovernmental Panel on Climate Change was that climate change is proceeding faster and worse than was stated in the fifth report. Electromobility is being rolled out at an increasing pace, and digital transformation is advancing at an unabated pace.

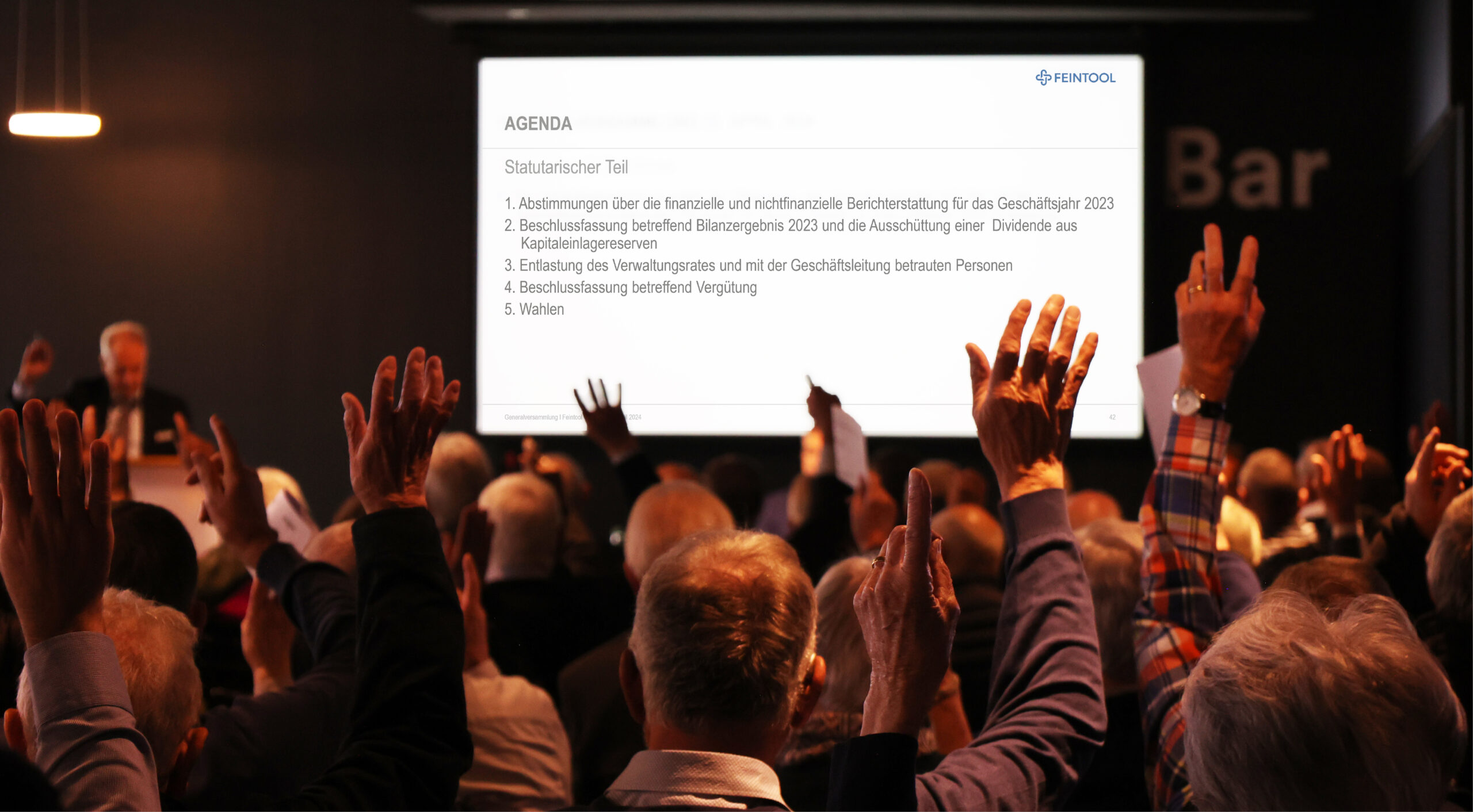

Much has changed, evolved, in a short time since Feintool’s first Technology Forum was held in April of this year. Stefan Etzold, Head of Sales at Fineblanking Technology, staked out the playing field in his welcoming remarks. Nothing is as constant as change, was the message of his opening remarks to the more than 70 participants at the second Feintool Technology Forum.

Global challenges have been guiding the development of new technologies at Feintool not only since yesterday. In response to climatic, economic and technological changes, Feintool builds presses that set new standards in terms of durability, quality, efficiency and resource consumption.

It is our ambition to actively shape the paradigm shift in production towards consistent sustainability thanks to longer service life, efficient product use and targeted – but at the same time as comprehensive as possible – functionality with the further development of our press portfolio.

For Feintool, sustainability therefore means: Taking responsibility and achieving concrete goals.

At the same time, Feintool is tapping into the potential offered by electromobility.

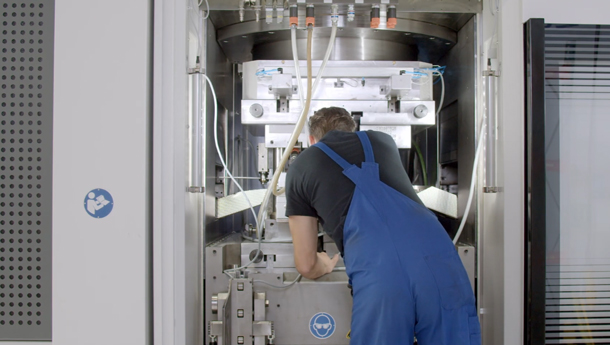

On their tour of the plant in Jona, Feintool CEO Knut Zimmer and Markus Schaltegger, Head of the Technology Division, made it possible for the webinar participants to experience how Feintool is researching and working on the technologies of the electromobile future.

The FB one fineblanking press is a significant leap forward in innovation. Feintool’s latest generation of presses incorporates a wealth of new technologies that enable fineblanking and forming at a new level of performance. This can be seen in four indicators that are crucial for the customer and his production:

1. Energy & Environment

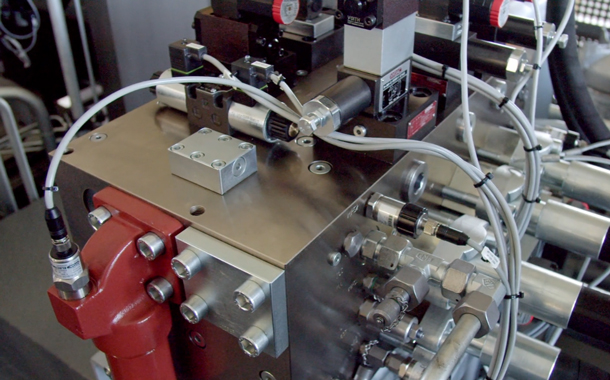

The FB one offers significant energy savings and improved environmental compatibility. It reduces energy consumption by 30 to 40 percent. This is primarily due to the innovative hydraulic concept. It requires significantly less energy for the same output.

Further energy savings result, for example, from the massively reduced oil tank. A 700-ton FB one requires only a third of the previous oil quantity. This is made possible by active degassing of the oil under vacuum, which has the additional positive effect of significantly extending the service life of the lubricant.

2. Transformation & Flexibilization

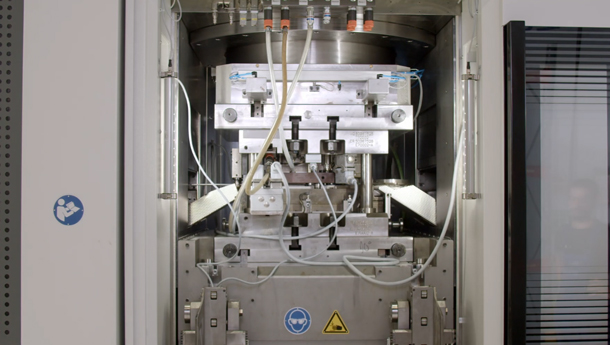

In view of the digital transformation of the industry, the FB one enables the entire fineblanking process to be made more flexible. The press, which is designed according to the modular principle, allows very flexible arrangement – or combination – of machine components.

One example is the new design of the feeders and waste shears of the FB one. Depending on the production requirements, a roller or gripper feed can be selected for the discharge. The highlight is that the infeed and discharge feeds are identical across all sizes. This makes maintenance and spare parts management much easier.

3. Performance & Economy

In fineblanking, a new performance class means increasing the number of strokes and the availability of the press – without sacrificing precision and quality.

This is based on a fundamental redesign of a whole series of technical details: Ventile technology, hydraulic direct drive, flexible use of tools, part output, dimensioning of the tool installation space, the cutting stroke – our engineers have rethought everything to raise output and availability to a new level.

4. Connectivity & Ergonomics

An important innovative feature is the connectivity of the FB one and its consistently ergonomic operating concept. At this point, the FB one comes up with forward-looking Industry 4.0 concepts, such as predictive maintenance, integrated audit trail, convenient mold parameterization and a user-friendly multi-touch display.

Machine downtime is minimized, seamless tracking of production history is ensured, and optimal ease of use becomes standard.

And what do the customers say?

The inside view is one thing, the outside view is another. René Aerts, Chief of Staff at ART Group, has been an FB one customer from the very beginning. As the voice of the market, he answered Stefan Etzold’s questions in the last part of the webinar.

The ART Group is a conglomerate of different companies that started fineblanking sixty years ago and today supplies OEM customers all over the world in the high-end sector from Tillburg in Holland.

René Aerts outlined ART Group’s vision for the future in light of the constant pursuit of operational excellence. Innovativeness and excellence are the cornerstones to ensure a successful and sustainable future for the company, the Chief of Staff explained. In 2017, ART Group therefore decided to invest in a state-of-the-art serial production facility that operates at the cutting edge of technology and the best available performance standard in terms of energy, environment and ergonomy. «Knowing that in Feintool we have a partner capable of developing press systems at the highest level like no other, we decided to purchase an FB one.»

ART Group carried out the first test cycles in Jona with its own fineblanking tools. «We were very impressed with the repeatability of the system. The stroke rate was also very promising.» Some fine-tuning was then needed to optimize the system and processes. «But we had confidence that Feintool would solve these problems», says René Aerts. Throughout the entire process, contact between Feintool and the ART Group project team was intensive and communication transparent at all levels. «Today, we are producing with existing tools in series production and developing new tools to take full advantage of the press system.»