Impermeable stacking enables integrated cooling for electric motors.

The efficiency and performance of motors are crucial in electromobility. This includes, in particular, the factors of energy efficiency, stack stability, and their impermeability to cooling fluid. The glulock MD (Multiple Dots) bonding process promises tight and stable electric motors, even in the high-temperature range.

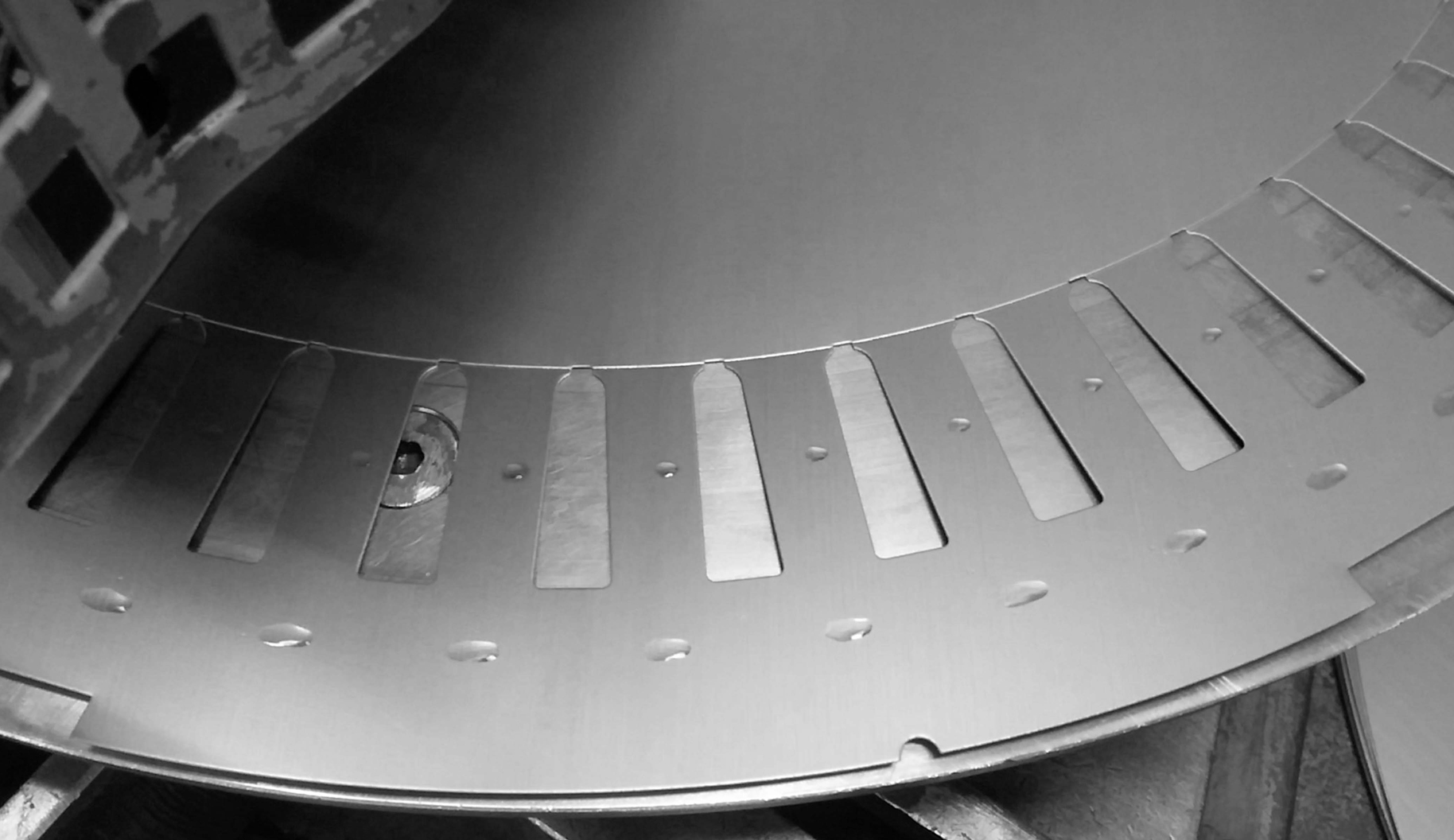

Increased efficiency in electric motors are not only goals set by the automotive industry, but are also anchored in the regulation of efficiency classes for industrial motors. This required increase in efficiency is achieved by modern grades of electrical sheet. At the same time, the thickness of the sheet is reduced, as this allows electrical efficiency to be increased. In the area of joining methods, market analyses show a trend towards bonding the laminates. This can increase performance and reduce losses in the motor. Feintool offers glulock MD, a unique joining technology with decisive, commercial and technical advantages for customers.

High efficiency and stable at high temperatures

Compared to conventional package types, glulock® proves to be cost-effective, precise in design and with significant improvements in stack tolerances for parallelism, shape accuracy, runout and length tolerance. In addition, the output power is increased or, conversely, the motor size is reduced. Noise generation and eddy current losses are also reduced. Even the stacking of thin sheets (0.1 mm) can be realized with glulock®. glulock HT (High temperature) is a continuation of the series-proven gluing method. It improves strength and media resistance and enables increased temperature resistance up to 180° C. For example, glulock HT can be used in ATF oil within temperature class H.

Sealing as a new challenge

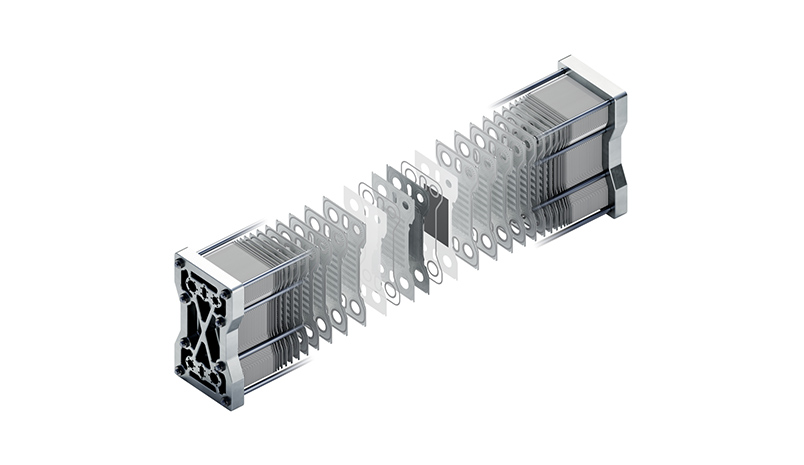

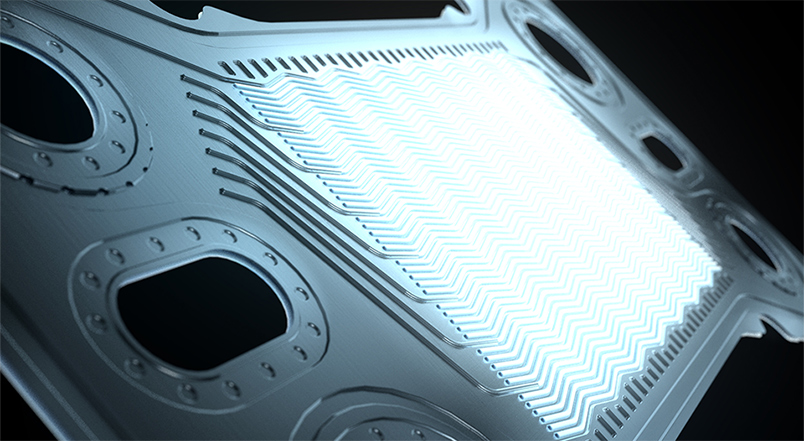

Further developments in electric motors show that, in addition to the growing mechanical and thermal requirements, their cooling also has potential for optimization. The trend is for motors not to be cooled externally, but to have cooling integrated into the rotors and stators. This requires impermeable stacking, sealing and surface bonding. glulock MD is the further development of the glulock® technology and offers the solution for the new market requirements. With glulock MD, it is possible to place several glue dots on the sheet in such a way that an almost full-surface bonding is ensured. Tests have already confirmed the required tightness. The bonding on the yoke and tooth ensures stability.

The patented bonding processes offer the ideal solution for electric motors with high quality requirements in terms of stability, electrical efficiency, media and temperature resistance, and leak tightness. With these prerequisites, it is possible to achieve decisive advantages in cooling options as well as to significantly advance the development of electromobility. Markus Lock, Head of Engineering, is convinced: “With the existing technology portfolio, its consistent further development, and our proximity to customers and the market, I am firmly convinced that we have already found the right answers to the requirements of the future.”

Short profile

Feintool is an internationally active technology and market leader in fineblanking, forming and electrolamination stamping for processing steel sheets. Cost-effectiveness, superior quality and productivity characterize these technologies.

As an innovation driver, Feintool constantly pushes the boundaries of these technologies and develops intelligent solutions to meet its customers’ requirements: On the one hand, high-performance fineblanking systems with innovative tools and state-of-the-art manufacturing processes, and on the other, complete processes for precise fineblanking, forming and stamped electrical sheet components in high volumes for demanding automotive and industrial applications.

These processes support the trends in the automotive industry. Feintool acts as a project and development partner in the areas of lightweight construction/sustainability, module variations/platforms and alternative drive concepts such as hybrid and electric drives.

Founded in 1959 and headquartered in Lyss, Switzerland, the Group runs its 19 production plants and technology centers in Europe, the United States, China and Japan, ensuring close proximity to its customers. Around the globe, about 3 500 employees and 100 apprentices are at work on new solutions to create key advantages for Feintool customers.