Für eine neue Klasse von Brennstoffzellen

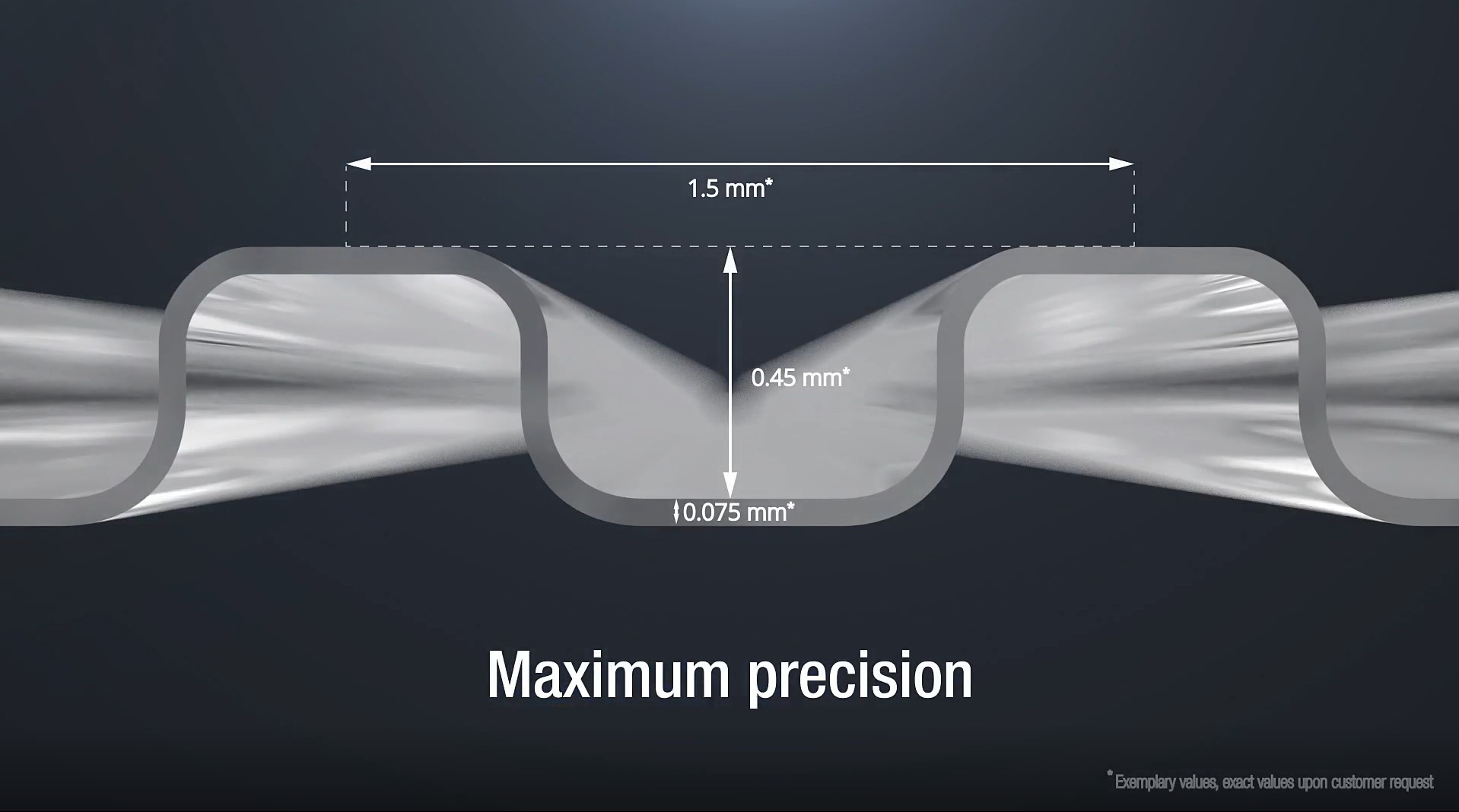

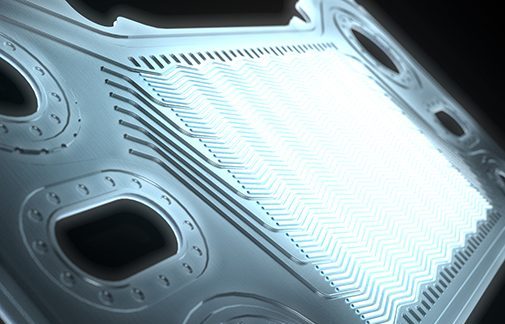

Feinforming ermöglicht die Bearbeitung von Metallen in dünnsten Materialstärken mit minimalen Toleranzen und höchster Präzision – entscheidend für die Herstellung von Bipolarplatten, die in Brennstoffzellen und Elektrolyseuren eingesetzt werden.

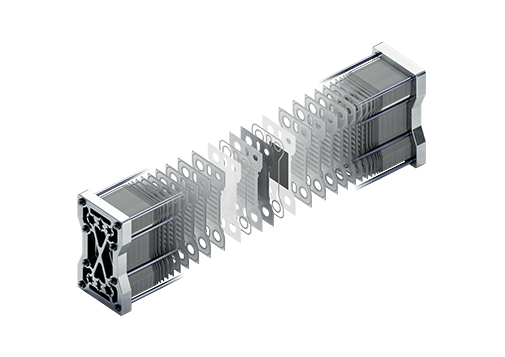

Wir optimieren den Materialeinsatz, die konstruktive Umsetzung und die Produktion, um die Kosten zu senken und die Effizienz der Brennstoffzellentechnologie zu erhöhen.

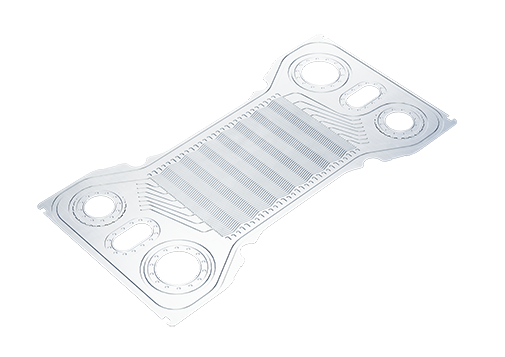

Herstellung von Bipolarplatten für Brennstoffzellen und Elektrolyseure